Final Sterile Filtration & Filling

Final sterile filtration and filling are the last steps in the production process and play a pivotal role in assuring drug product sterility and safety for patients. Our Mobius® single-use components and solutions streamline these complex operations and reduce the risks of contamination, offering speed and flexibility while maintaining the highest standards of safety and quality.

Mitigate Risks in Integrity Testing with Our Mobius® iPUPSIT Filtration System

Our new Mobius® iPUPSIT Filtration System automates pre-use post-sterilization integrity testing (PUPSIT) of critical sterilizing filters and mitigates the potential risks of contamination, test failures, and subsequent batch loss. This pre-engineered system simplifies highly complex manual operations, reducing the likelihood of operator error while providing flexibility for different single-use filtration configurations.

- Optimize Footprint: Compact design to fit in tight cleanroom spaces

- Gain Flexibility: Modular system compatible with single and redundant assemblies from Millipak Final Fill 20 to Opticap XL 10 Capsule Filters

- Tailor Automation: Multiple options from local recording to full automation

- Maximize Product Recovery: Optimized system & consumables engineered to reduce yield loss

Products

Filters for Aseptic Filtration

Gas filters are critical to maintaining a boundary between the environment and the aseptic fluid path. Filters containing our sterilizing-grade Millipore Express® SPG (Sterile, Phobic Gamma) hydrophobic membrane are the preferred choice for gas filtration and venting in single-use applications.

Millipak® barrier filters contain both hydrophilic and hydrophobic sterilizing-grade Durapore® membranes, allowing the flow of both liquid and gas. These filters simplify PUPSIT by maintaining the sterility of the system while removing the constrains of a flush bag or a can.

For sterile filtration of aqueous liquids, filters containing our proven Durapore® polyvinylidene fluoride (PVDF) membrane offer low protein binding and superior robustness. For some processes, our trusted polyethersulfone (PES) Millipore Express® membrane filters may be a better option.

Our membrane filters are available in multiple filter formats and are fully scalable from small-scale tools to pilot and production scale manufacturing. Capsule filters are compatible with autoclave or gamma irradiation and are also available pre-sterilized for maximum flexibility.

- Millipak® Final Fill filters contain a Durapore® PVDF membrane available in multiple pore sizes. The capsule’s stacked disc format minimizes product hold-up volume.

- Durapore® 0.22 µm filters contain a single layer of 0.22 µm sterilizing-grade PVDF membrane and are robust, low protein binding, and available in multiple filter formats.

- Millipore Express® SHF (Sterile, High Flux) filters contain a single layer of 0.2 µm sterilizing-grade PES membrane and offer high flux and extremely broad chemical compatibility.

- Durapore® 5.0 µm PVDF membrane filters remove aggregates and particles from sterile bulk liquids filters and are available in multiple filter formats.

Single-use Filling Assemblies for Fill Finish Processes

Our single-use filling assemblies are custom designed to integrate with various brands of isolator or RABS filling machines. Our Mobius® experts collaborate with you and your machine vendor to ensure the system is designed to your needs and meets regulatory expectations. Our diverse portfolio of single-use components can be easily integrated into your filling system, and includes:

- Sterile connectors

- 2D header bags up to 50 L

- Dosing pump tubing

- Molded TC manifolds

- Beta bags

- Single-use filling needles

The result is a single-use final fill system that’s ready to use out of the box, featuring modular, fully optimized assemblies. These systems are replicable, scalable, and simplify technology transfer across multiple sites.

Please contact your local representative for help with designing a custom final filtration and filling assembly.

Regulatory Compliance

Complementing our product portfolio, the Emprove® Program consolidates comprehensive product-specific testing data, quality statements, and regulatory information in a readily available format to simplify your compliance needs.

Related Resources

- Data Sheet: Mobius® iPUPSIT Filtration System - For reducing risks in final sterile filtration

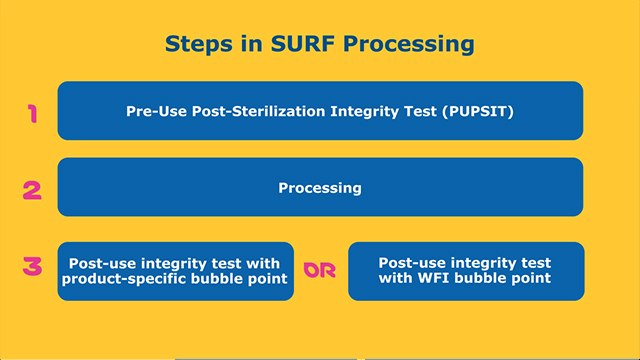

EU GMP Annex 1 requires for sterilizing grade filter that is used to sterilize a fluid should be pre-use post sterilization integrity tested (PUPSIT). While single-use assemblies facilitate implementation of PUPSIT, manual intervention creates multiple areas of concern including operator error and maintaining sterility of the drug product.

- Article: Millipore Express® Express Sterilizing-Grade Membrane Filters Selection Guide

Discover various Millipore Express® sterilizing-grade membrane filters for liquid filtration in aseptic drug production.

- Article: Aseptic Filter Formats: Selection Guide

This technical article provides a high level overview of different formats available to help guide product selection.

- Technical Note: Improved Product Recovery Using Blow-down with Millipak® Final Fill Filters

In this tech note, we compare hold-up volume of both pleated and stacked disc filters and highlight the benefits of filter blow-down for maximizing product recovery.

- Application Note: Establishing Product Specific Bubble Point Values for Sterilizing-Grade Filters

Integrity testing sterilizing filters is a fundamental requirement of critical process filtration applications in the pharmaceutical industry.

- Technical Note: Millipak® Final Fill Filters Reduce Contamination Risks and Simplify Filtration System Design and Operation

This tech note summarizes the results of microbial challenge studies that confirm the aseptic multipurpose port (AMPP) prevents microbial contamination entering the flow path.

- White Paper: Adoption Of Single-Use For Final Filtration

Single-use systems (SUS) are now used routinely in the manufacture of biologics in both upstream and downstream operations.

- Data Sheet: Durapore® Family Guide

We offer a full portfolio of membrane filters to meet the needs of different bioprocess applications.

- Specification Sheet: Single-Use Filling Needles Integrated into Mobius® Final Fill Assemblies

Mobius® single-use filling needles are available in four different styles, several different sizes, and are compatible with filling machines manufactured by various machine vendors.

To continue reading please sign in or create an account.

Don't Have An Account?