Sign In to View Organizational & Contract Pricing.

Select a Size

About This Item

Linear Formula:

CH2=C(CH3)COO(CH2)11CH3

CAS Number:

Molecular Weight:

254.41

UNSPSC Code:

12162002

NACRES:

NA.23

PubChem Substance ID:

EC Number:

205-570-6

Beilstein/REAXYS Number:

1708160

MDL number:

SMILES string

CCCCCCCCCCCCOC(=O)C(C)=C

InChI

1S/C16H30O2/c1-4-5-6-7-8-9-10-11-12-13-14-18-16(17)15(2)3/h2,4-14H2,1,3H3

InChI key

GMSCBRSQMRDRCD-UHFFFAOYSA-N

assay

96%

contains

500 ppm MEHQ as inhibitor

Quality Level

bp

142 °C/4 mmHg (lit.)

mp

−7 °C (lit.)

density

0.868 g/mL at 25 °C (lit.)

Related Categories

General description

Lauryl methacrylate is a monomer that belongs to the class of methacrylate esters, is extensively employed in the manufacturing of diverse polymer materials. Polymers derived from lauryl methacrylate can be employed in personal care products, where they contribute to the formulation′s rheology, stability, and film-forming properties.

Application

Lauryl methacrylate can be used as a monomer:

- To prepare polymeric co-stabilizer by free-radical copolymerization.

- To fabricate fluorine-less superhydrophobic cotton fabrics via graft polymerization process.

- In the synthesis of prepolymers that are used in oil absorbents.

signalword

Warning

hcodes

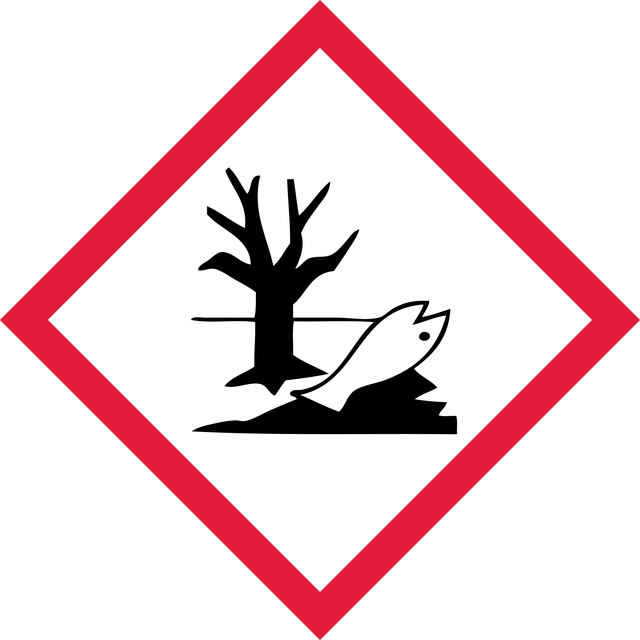

Hazard Classifications

Aquatic Acute 1 - Aquatic Chronic 1 - Eye Irrit. 2 - Skin Irrit. 2 - STOT SE 3

target_organs

Respiratory system

Storage Class

10 - Combustible liquids

wgk

WGK 1

flash_point_f

224.6 °F - closed cup

flash_point_c

107 °C - closed cup

ppe

Eyeshields, Gloves, type ABEK (EN14387) respirator filter

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Efficiency of ligands in atom transfer radical polymerization of lauryl methacrylate and block copolymerization with methyl methacrylate

Raghunadh VD, et al.

Polymer, 45(10), 3149-3155 (2004)

Comparison of thermal and photo polymerization of lauryl methacrylate monolithic columns for CEC

Bernabe Zafon V, et al.

Electrophoresis, 30(11), 1939-1936 (2009)

Dennis L Waldron et al.

Nanotechnology, 28(9), 095205-095205 (2017-01-07)

The results are presented for luminescent solar concentrators (LSCs) fabricated with poly(lauryl methacrylate-co-ethylene glycol dimethacrylate) (P(LMA-co-EGDMA)) and Angstrom Bond, Inc. AB9093 acrylic epoxy matrix, high quantum yield (> 70%) PbSe quantum dots (QDs) and silicon photovoltaic (Si PV) cells. LSCs

Shaping nanofiltration channels in a carbonaceous membrane via controlling the pyrolysis atmosphere.

Zheng Xing et al.

Physical chemistry chemical physics : PCCP, 19(32), 21426-21435 (2017-08-02)

This work investigates the effect of atmosphere on pyrolysis of a polymer matrix (precursor) for directing its transformation towards more disordered graphene species and smaller graphitic nanograins. These two structural characteristics are crucial to the generation of nano-channels (NCs) pertinent

The Fabrication of Very Small Miniemulsion Latexes from N-Stearoylglutamate and Lauryl Methacrylate: Evidence for Droplet Budding

Yildiz U, et al.

Macromolecular Chemistry and Physics, 204(16), 1966-1970 (2003)

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service